C-1540 Cone Crusher - Raco Rappresentanze

C-1540 Cone Crusher - Raco Rappresentanze

C-1540 Cone Crusher - Raco Rappresentanze

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

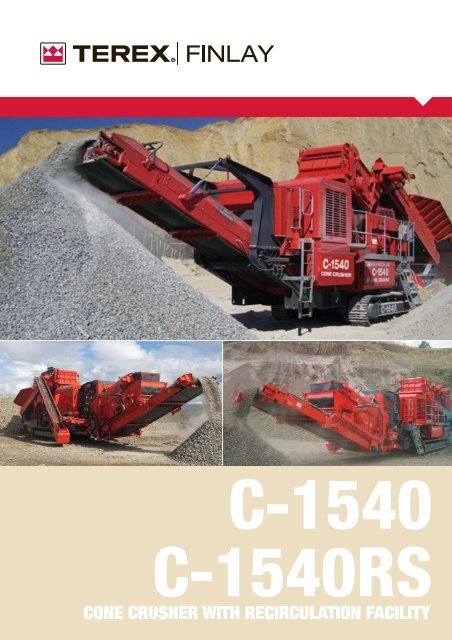

RC-<strong>1540</strong>C-<strong>1540</strong>RSCONE CRUSHER WITH RECIRCULATION FACILITY

Innovation,Reliabilty &Performance...Introducing the Terex ® Finlay C-<strong>1540</strong> <strong>Cone</strong><strong>Crusher</strong> - the most advanced mobile trackedcrusher solution for producing high qualityaggregates!!The C-<strong>1540</strong> delivers efficient product throughput, high material reductionratios, excellent product shape & is suitable for secondary & tertiaryapplications.Incorporating the proven Terex ® 1000 <strong>Cone</strong> Chamber, the C-<strong>1540</strong> boastsa direct hydrostatic drive with an advanced electronic control system,large capacity feed hopper, metal detection & contaminant purge systemas standard features.Throughput capacity & performance of this unique system can beenhanced with the optional pre-screen system.Hopper Feeder SystemThe feed hopper has a capacity of5m 3 (6.5yd 3 ) and incorporates aseries of crash bars to reduceimpact on the feed belt. Optionalhopper extensions are availablethat increase the capacity to 8m 3(10.5yd 3 ).The hopper incorporates anautomatic variable speed conveyorto maximise throughput.The hopper has a drop down reardoor for auxillary crusher feed.

C-<strong>1540</strong> <strong>Cone</strong> <strong>Crusher</strong>Metal Detection and Purge systemThe hopper feeder is fitted with a metal detection andpurge system. When any metal objects are detected onthe feed conveyor, the feeder belt automatically stops andthe warning beacon flashes to alert the operator. Thefeeder belt can be hydraulically retracted to its purgeposition, then the contaminated section of material isejected onto the purge chute. Once the contaminatedmaterial has been removed from the belt it can bereturned to its feed position to resume crushing.At a Glance Proven Terex ® 1000 <strong>Cone</strong> Chamber (40” head diameter)Metal detection system on feed belt with purge facilityCat C9 Acert 261kW(350HP) water cooled diesel engineDirect hydrostatic variable speed cone driveAdvanced electronic control systemVariable feeder speed control to maintain choke feed conditionmaximising reduction & manganese lifeHopper capacity of 5m 3 (6.5yd 3 ) with impact reducingcross bars.Controllable discharge system to purge metal contaminantsfrom beltLong throw eccentric, medium coarse concave (maximumfeed size 160mm / 6.3”)Tramp metal relief system with automatic reset

C-<strong>1540</strong> <strong>Cone</strong> <strong>Crusher</strong>Pre-screen 1830mm x1220mm ( 6’x 4’ )Single deckTransfer conveyor 1000mm (40”) Belt<strong>Cone</strong> HeadDiameter:Net EnginePower:Portability:OperatingWeight:Hopper / Feeder 5m³ (6.5yd³) Capacity 1050mm (42”) Belt width Metal detection system1000mm40”261kW350HPTracked38,300kg *84,435lbs*Contamination purge chuteTracks 3.8m (12’ 6”) Sprocket centres 500mm (20”) Shoe widthOPTIONAL EQUIPMENT FEATURES- Pre-screen system - 1.83m x 1.22m (6'x4') single deck screen with 1000mm - Cold Climate lubrication kit ( For below -10 degree celsius (14 o F) ambient )(40") transfer conveyor and dust cover complete system folds for transport, - Extra coarse concave - max feed size 195mm (7.7”) (check leadtime)16mm ( 5 /8”) aperture mesh fitted unless specified otherwise.- Coarse concave - max feed size 175mm (6.9”)(check leadtime)Requires - 1 nr auxiliary drive 1- Sand concave - max feed size 63mm (2.5”) (check leadtime)- Hydraulically driven water pump for dust suppression.* NOTE MUST TAKE SHORT THROW ECCENTRIC ( BELOW )Requires 1 nr auxiliary drive 1- Short throw eccentric (check leadtime)- Main conveyor dust cover- Electric pump refuelling kit* NOTES:- Special Paint Colour (if different from Finlay Orange RAL 2002). RAL must be 1) Only 2 nr auxiliary drives are available in totalprovided2) When hot climate cooler pack is selected must also take main conveyor Dust- Wear resistant liners 6mm (1/4”) for feed hopperCovers & Hot Climate lubrication pack options- Manual extensions for feed hopper (total capacity 8m³ / 10.5yd³)- Radio remote System: Operational controls of machine (auto start/stop) & trackmovement- Belt weigher for main conveyor- 1 nr stockpiler drive. Requires 1 nr auxiliary drive 1- Lighting mast for catwalk- Hot climate lubrication kit ( For above +30 degree celsius (86 o F) ambient )- Hot Climate cooler pack for ( For above +40 degree celsius (104 o F) ambient )Requires 1 nr auxiliary drive 1&2

Two VersatileMachines onOne Chassis...The C<strong>1540</strong>-RS provides the versatility of acrushing & screening plant on one chassis forsecondary & tertiary applications.The C-<strong>1540</strong>RS passes the crushed product to the onboard 3.66m x 1.52m (12’ x 5’) sizingscreen. Oversize material is then passed back to the cone crusher for re-crushing via thetransfer conveyor/recirculation conveyor system. Fines material passes through the screen,and is stockpiled using the onboard conveyor. An additional stockpile conveyor option canbe mounted to the machine along with a transfer conveyor to provide a stockpile of middlegrade material. The additional stockpiler option must be removed for transport.Detachable ScreenThe recirculation screen can berapidly detached if necessary. Thisallows the machine to be moreconveniently moved around site &provide more efficient operation ifrecirculation or sizing is notrequired. The system can bedetached or re-attached in under10 minutes without the need forlifting equipment. The coresoftware can recognise & adjust tosuit automatically.

C-<strong>1540</strong>RS <strong>Cone</strong> <strong>Crusher</strong>With sizing screen and recirculation facilityAt a GlanceProven Terex® 1000 <strong>Cone</strong> Chamber (40” head diameter)Metal detection system on feed belt with auto stop & purgeCat C13 Acert 328kW(440HP) water cooled diesel engineDirect hydrostatic variable speed cone driveAdvanced electronic control systemVariable feeder speed control to maintain choke feedmaximising reduction & manganese lifeHopper capacity of 5m 3 (6.5yd 3 ) with impact reducingcross bars. Controllable discharge system to purge metal contaminantsfrom belt Long throw eccentric, medium coarse concave -max feed size 160mm (6.3”) Tramp metal relief system with automatic reset High quality finished product with recirculation feature Combined crusher & screener on one chassis

C-<strong>1540</strong>RS <strong>Cone</strong> <strong>Crusher</strong>Contamination purge chuteTransfer conveyor 1000mm (40”) BeltPre-screen 1830mm x1220mm (6’x 4’) Single deckHopper / Feeder 5m³ (6.5yd³) Capacity 1050mm (42”) Belt width Metal detector systemChassis Heavy duty chassis<strong>Cone</strong> Chamber Ø40” (1000mm) h Direct HydrostaticSTANDARD FEATURES:Engine:- Caterpillar C13 Acert 328 kW (440HP) water cooled engineChamber:- Terex 1000 <strong>Cone</strong> chamber, 1000mm (40") head diameter- Long throw eccentric, medium coarse concave- max feed size 160mm (6.3”)- Hydrostatic cone drive with electronic speed control system- 'On the fly' hydraulically adjustable closed size setting with monitoring system- Mantle/concave wear indicator- Tramp metal relief system with automatic resetHopper / Feeder:- 5m³ capacity (6.5yd³), with impact reducing cross bars- Low level drop down rear feed point- Hydraulic retraction system (foldable for transport)- 1050mm (42") wide feed belt- Metal detection system on feed belt with 'auto-stop' feature- Controllable discharge system to purge metal contaminants from belt- Heavy duty, high torque hydraulically driven feed belt- Wear resistant liner plates 10mm (0.4”) fitted to feed-in end of hopperMain Conveyor:- 900mm (36") product conveyor belt- High spec scraper at head drum- Wear resistant liners 15mm (0.6”) at crusher discharge pointRe-circulating System:- 3.66m x 1.52m (12' x 5') two deck screen- Top deck mesh fitted to screen - 40mm (1.6”) aperture fitted unless specifiedotherwise- Oversize transfer conveyor, re-circulating conveyor and fines conveyor fitted asstandard- Quick detach screen and fines conveyorNote:- Middle grade transfer conveyor is not fitted, this is only an optionGeneral:- Galvanised catwalk c/w handrail, kick board and access ladders- Heavy duty track unit, sprocket centres 3.8m (12’6”), pad width 500mm (20”)- Hand held track control set with 5m (16’ 5”) connection lead- Single speed tracks with soft start- Safety guards to 'M&Q' specification- Multiple easy access low level greasing points- Two auxiliary drives* standard on basic machine- Emergency stops (7 nr)- Dust suppression system (manifold, 3 bars, piping)

Powerunit CAT C13 328kW (440HP) Hydrostatic transmission Electronic control system Catwalk accessMain Conveyor 900mm (36”) Belt 3.3m (10’ 10”) Discharge<strong>Cone</strong> HeadDiameter:Net EnginePower:Portability:OperatingWeight:1000mm40”328 kW440 HPTracked45,600 kg *100,528lbs** Note: With optional pre-screenFines ConveyorScreen box 1400mm (55”) Belt width12’ x 5’ top deck (3.66m x 1.52m)3.0m (9’ 10”) Discharge height 10’ x 5’ bottom deck (3m x 1. 52m)Oversize Transfer Conveyor 500mm (20”) belteaddriveTracks 3.8m (12’ 6”) Sprocket centres 500mm (20”) Shoe widthRecirculation conveyor Folds for transport 500mm (20”) chevronOPTIONAL EQUIPMENT FEATURES- Pre-screen system - 1.83m x 1.22m (6'x4') single deck screen with 1000mm(40") transfer conveyor and dust cover. Complete system folds for transport,16mm (0.6”) aperture mesh fitted unless specified otherwise. Requires1 nrauxiliary drive 1- Hydraulically driven water pump for dust suppression. Requires 1 nr auxiliarydrive 1- Main conveyor dust cover- Electric pump refuelling kit- Special Paint Colour (if different from Finlay Orange RAL 2002). RAL must beprovided- Wear resistant liners (6mm/ 1 /4”) for feed hopper- Manual extensions for feed hopper (total capacity 8m³ / 10.5yd³)- Radio remote System: Operational controls of machine (auto start/stop) & trackmovement- Belt weigher for main conveyor- 1 nr stockpiler drive. Requires 1 nr auxiliary drive 1- Lighting mast for catwalk- Hot climate lubrication kit ( For above +30 o C (86 o F) ambient )- Hot Climate cooler pack for ( For above +40 o C (104 o F) ambient )Requires 1 nr auxiliary drive 1&2- Cold Climate lubrication kit (For below -10 o C (14 o F) ambient)- Extra coarse concave - max feed size 195mm (7’7”) (check leadtime)- Coarse concave - max feed size 175mm (6.9”) (check leadtime)- Sand concave - max feed size 63mm (2.5”)(check leadtime) NOTE MUST ALSOTAKE SHORT THROW ECCENTRIC (BELOW)- Short throw eccentric (check leadtime)- Bottom deck meshes and tensioner brackets (For re-circulating system)- 20mm ( 3 / 4 ”)- aperture mesh fitted unless specified otherwise- Middle grade transfer conveyor and chute (For re-circulating system) 3- Middle grade stockpiling conveyor - Separate transport load (For re-circulatingsystem) 4* NOTES:1) Only 2 nr auxiliary drives are available in total2) When hot climate cooler pack is selected must also take main conveyor DustCovers & Hot Climate lubrication pack options3) When middle grade transfer conveyor & chute is selected MUST also takebottom deck meshes & tensioner bracket option4) When middle grade stockpiling conveyor is selected MUST also take bottomdeck meshes & tensioner bracket & middle grade transfer conveyor options

C-<strong>1540</strong> <strong>Cone</strong> <strong>Crusher</strong>Transport Position16.9m (55’ 5”)2.8m (9’ 1”)3.45m (11’4”)Working Position15.79m (51’10”)3.77m (12’4”)4.75m (15’7”)Working Height Working Length Working Width Transport Height Transport Length Transport Width Weight4.75m (15’7”) 15.79m (51’10”)3.77m (12’4”)3.45m (11’4”) 16.9m (55’5”)2.8m (9’1”)38300 Kgs *84,435 lbskg*Note: With optionalpre-screen

C-<strong>1540</strong>RS <strong>Cone</strong> <strong>Crusher</strong>With sizing screen and recirculation facilityTransport Position18.76m (61’ 7”)3.1m (10’ 2”)3.5m (11’ 6”)Working Position19m (62’4”)4.7m (15’ 5”)4.75m (15’ 7”)Working Height Working Length Working Width Transport Height Transport Length Transport Width Weightkg4.75m (15’7”)19m (62’ 4”) 4.7m (15’5”)3.5m (11’6”)18.76m (61’ 7”) 3.1m (10’2”)45 600 Kgs*100 528 lbs*Note: With optionalpre-screen

Drumquin Road,Omagh Co. Tyrone N.Ireland BT78 5PNTel: + 44 (0) 28 82 418 700Fax: + 44 (0) 28 82 244 294E-mail: sales@terexfinlay.comWeb: www.terexfinlay.comTerex USA, LLC909 17th Street NECedar Rapids, IA 52402 USATel: +1 (800) 821-5600 or +1 (319) 363-3511Fax: +1 (319) 399-4871E-mail: info@cedarapids.comWeb: www.terexfinlay.comEffective 20. 02. 2009. Product specifications and prices are subject to change withoutnotice or obligation. The photographs and/or drawings in this document are for illustrativepurposes only. Refer to the appropriate Operator’s Manual for instructions on the properuse of this equipment. Failure to follow the appropriate Operator’s Manual when using ourequipment or to otherwise act irresponsibly may result in serious injury or death. Theonly warranty applicable to our equipment is the standard written warranty applicable tothe particular product and sale and Terex makes no other warranty, express or implied.Products and services listed may be trademarks, service marks or trade-names of TerexCorporation and/or its subsidiaries in the USA and other countries. All rights are reserved.Terex® is a registered trademark of Terex Corporation in the USA and many othercountries.Copyright 2009 Terex Corporation.