Humans have been building cars for well over a century now, and under almost every hood has sat an internal combustion engine. For the past 100 years, its principle has remained the same: air and fuel go in, an explosion happens in the cylinders, and power shoves you onward. But every year, engineers hone the internal combustion engine to go faster and farther, developing it to be more efficient than before, producing the kind of power you used to only see on supercars. The state of the internal combustion engine could have never gotten this far without these major leaps. Here's how we got to this point.

1955

Fuel injection

Before fuel injection, meting out gasoline into a combustion chamber was an imprecise and finicky process. Carburetors frequently needed cleaning and rebuilding, and they were affected by weather conditions, temperature, and elevation. By comparison, fuel injection was simple: it helped an engine run smoother, idle steadier, run more efficiently, and eliminated the pesky chore of adjusting a choke every time you fired it up. Derived from wartime airplanes, it first made its way into an automobile in 1955. That year, Stirling Moss and Denis Jenkinson drove the Mercedes-Benz 300SLR race car across the grueling 992-mile Mille Miglia race in Italy, winning with a record that was never broken: 10 hours, 7 minutes, and 48 seconds.

Benz’s roadgoing version not only became the first production car with fuel injection, developed by Bosch, it was also the fastest car in the world. Two years later, Chevrolet gave the Corvette a “Fuelie” motor, with a Rochester Ramjet fuel injection system that managed to out-accelerate the 300SL. Still, it was Bosch’s electronically-controlled systems that worked their way into nearly every automaker in Europe, and by the Eighties, fuel injection had taken over the world.

1962

Turbocharging

The turbocharger is one of the jewels of engine advancements. A snail-shaped turbine cramming more air into a cylinder, it once allowed 12-cylinder World War II fighter planes to soar higher, faster, and farther. Guess what? It does the exact same on land. When the first turbocharged car debuted in 1962, it was not found underneath the clamshell hood of a featherweight European runabout, your BMW 2002 or Saab 99, but from the braintrust of General Motors, flush with cash and willing to try new tech.

Back then, the Oldsmobile Jetfire necessitated—with nearly every tankful of gas—the addition of “Turbo Rocket Fluid,” a whiz-bang Jetsons name for distilled water and methanol. GM abandoned the concept halfway through the decade. But by the end of the 1970s, the likes of BMW, Saab and Porsche took up the mantle, proved its worth in motorsport, and now every car has a turbocharger. Almost.

The turbocharger went from a dirty go-fast trick in your 930 Turbo to serving family duties in your Mazda CX-9, whose 2.5-liter engine was fitted with the first-of-its-kind Dynamic Pressure Turbo system in 2016. It's the "thumb over the garden hose" principle in action: constricted flow accelerates exhaust more quickly into the turbine, improving low-rpm responsiveness and reducing turbo lag. Plus, with stricter emissions and efficiency standards, it’s a necessary component in squeezing big-motor power out of the smallest and lightest engines. And the torque! You no longer need to shoot down any Messerschmitts to get that shoved-in-your-seat feeling.

1964

Rotary Engine

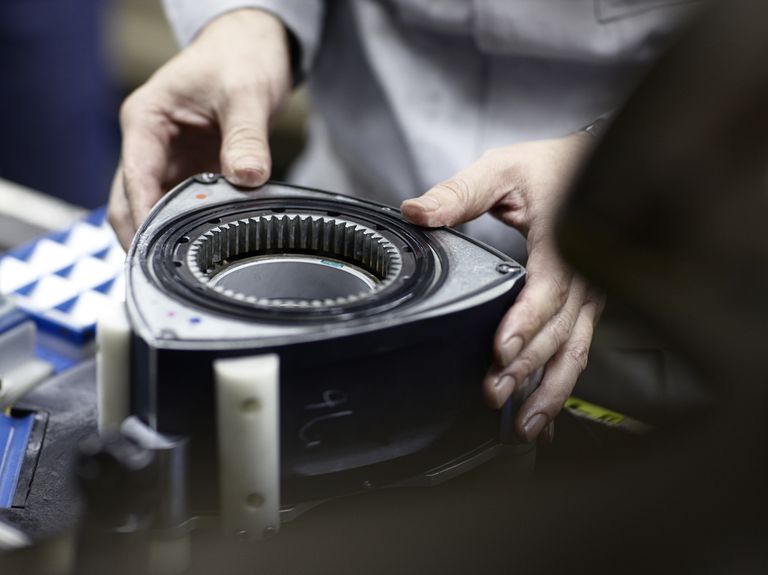

The only engine to truly break the mold—the only one to make it into production—was engineer Felix Wankel’s rotary wonder, a triangle inside an oval, spinning like a demon. By the very nature of its design, a rotary engine is lighter, less complex, and higher-revving than a typical box of pistons. Mazda and defunct German carmaker NSU were the first to sign on; in 1964, the NSU Spider became the first production car with a Wankel.

Mazda, however, was the only company that really ran with it—the first Mazda with a rotary was the 1967 Cosmo, the forebear of a long line of sports cars, sedans, and even an occasional pickup truck, all the way until the last RX-8 rolled off the line in 2012. The 2016 RX-Vision concept—unveiled at the 2015 Tokyo Motor Show—gave credence to a salacious rumor: that a dedicated band of engineers with nothing to lose are still developing the next great rotary engine, somewhere in a Hiroshima skunkworks.

1981

Cylinder Deactivation

The idea is simple. The less cylinders firing, the better mileage you get. How do you turn a V8 into a four-cylinder? If you were Cadillac circa 1981, you introduced the aptly-named 8-6-4 engine, which used electronically-controlled solenoids to close the valves on two or four cylinders. This was supposed to increase efficiency for say, cruising down a highway. But the ensuing unreliability and clumsiness was so notorious that nobody dared try it again for twenty years.

Now, across multiple manufacturers, the idea finally works—and it’s trickled down to smaller engines.

2012

Compression Ratios

The science works like this: inside an engine’s cylinder, the smaller you can compress the air and fuel, the more power you get when it explodes. The volume the piston can squeeze is the compression ratio. But manufacturers can’t crank up the compression ratios too high, or the mixture will ignite by itself; the subsequent “knocking” will tear an engine apart.

In the nadir of the 1970s, choked by smog regulations and forced to contend with unleaded gasoline, manufacturers built massive V8s that wheezed. These big boys were held back by painfully low compression ratios—the lead that was once in gasoline prevented knocking. With electronic fuel management and a better understanding of emissions control, engines began to produce more power while shrinking in displacement.

In 2012, Mazda’s SKYACTIV-G engine entered production with the highest compression ratio for a mass-produced engine, an astounding 14:1 (in America, 13:1), enabling it to extract the energy from almost every drop of gasoline without a bevy of smog equipment. Mazda’s next innovation took high compression to a new level. SKYACTIV-X uses Spark Controlled Compression Ignition (SPCCI) to ignite air/fuel mixtures with as little gasoline as possible, combining a diesel engine’s torque with a gasoline engine’s high-revving nature.

Even after a century, and even with alternate fuels and methods of propulsion, the internal combustion engine remains the biggest game in town. After so long, the basics haven’t changed. But there will always be a car company that is willing to introduce something new, and that continual refinement is key to keeping the internal combustion engine relevant in the years ahead.